|

I bought this Sunset GP7 many years ago with the intention of

removing the roof top air tanks and making it a freight unit. This was made

in Japan in 1984 as very early S Scale brass. My procrastination of starting this loco lead to the discovery

of PRR 8553, which ran with some frequency on the PRSL as a passenger unit.

The PRR was ordering diesel locomotives purpose built with the equipment

options almost to the point of pulling a particular train. So, this all fits

my PRSL, the torpedo tanks stay, and I added the PRR antennas along with some

other modifications and details. |

|

Reworking The

Drive

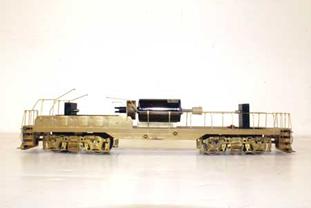

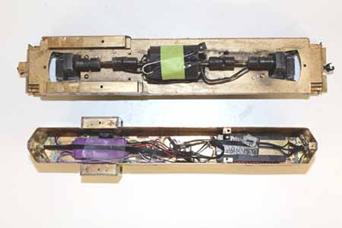

The drive was this horrid straight shaft running the length of

the interior with cogged pulleys and rubber belts down to cogged pulleys on the

trucks. The rubber belts likely took a set in sitting making for an awful

runner. I hated the rubber belt drive so much I did not even pause to take any

photos of it. I stripped out the parts in a frenzy and

SOLD them!

Photos by Bill Winans and Rich Gajnak

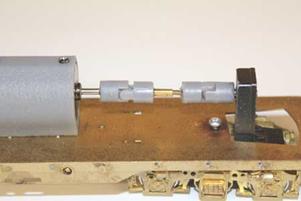

My delay starting this project worked well. The solution of using

some extraneous Overland F Unit gearboxes came to me and was a surprisingly

easy fix.

My first round of working on this project was in August 2013.

Below are some photos of the drive mock up. The lack of good driveshafts likely

killed progress for over 2 years. The later efforts are usually different and

better than I could have done previously. I have since moved away from wanting

to use flywheels, now depending more on the decoder programming for momentum.

And I did not have 3D printing capabilities in 2013 to come to the rescue in

solving the driveshaft problems.

December 2015

Progress on 8553 is reignited because my friend Bob Frascella

posted a photo of his completed 8551.

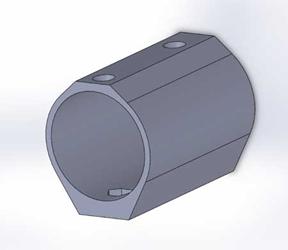

3D Printing

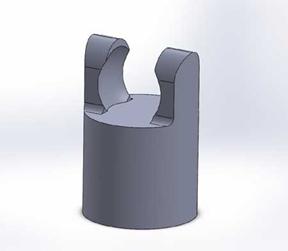

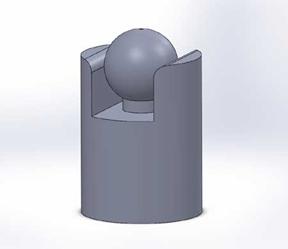

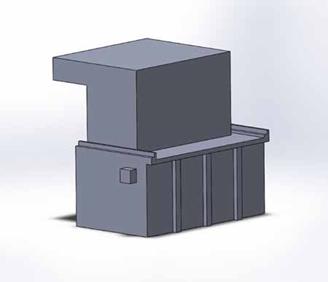

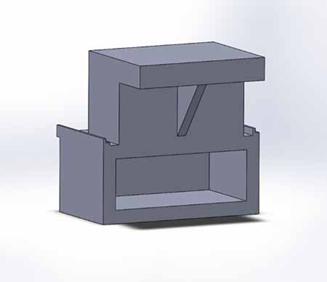

These

are the universal joints I designed and printed. There were various versions

but I settled on using square brass tube as the drive shaft because I needed

them to be telescopic. I probably could

have bought universal joints but making what I need is well apart of the

challenge and the FUN of it all for me. I got pretty lucky in the design of the

ball and socket. It mostly worked the first time with only some minor tweaking.

The 3D material is very slightly flexible when first printed. That is how I can

snap the socket onto the ball. But it gets harder and brittle in about a week

if exposed to light. I give it a liberal shot of oil, and think (HOPE) it will

be just as durable as plastic.

Universal Joints

Motor Mount

1-28-15

More work on the drive

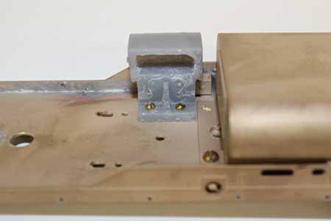

The

truck bolster screw originally attached right to the

floor. Since the U Joint hubs are now permanently attached to the gear tower

shafts accessing the truck screw would be difficult. I made these spanner bars

to be able to access 2 screws on either side of the driveshafts.

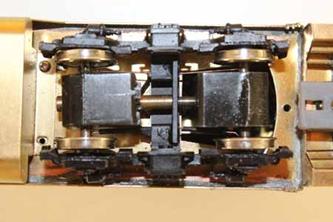

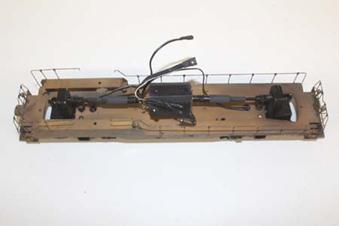

All Wheel Pickup

I

made my usual all wheel pick up system. I cut grooves in the back of the wheels

for the wiper wires to ride in. I use phosphor bronze wire only. All wheel

pickup is a LOT of work but it greatly improves performance.

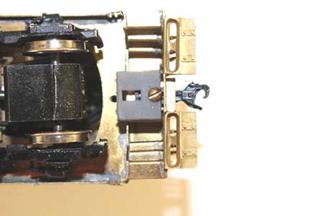

Couplers

The

model as built had a reasonable draft gear casting I hoped to use. But the

opening and coupler pad was originally designed for a Kadee #5 where I use

Kadee #802 for S Scale. I designed a custom box where there really is no

coupler box, at least in the draft gear. The 802 fits and centers well. The

opening is just a little wider than I would prefer, but does not bother me

enough to change it.

DCC

This

is the layout of the Tsunami decoder and speaker I chose. The decoder is not

visible in the roof of the cab. The speaker is available from RailMaster. http://www.railmasterhobbies.com/Speakers.htm

I use lots of Miniatronics plugs to make working on it easy. There is a 4 wire

plug to separate the shell from the drive for “power up – motor down” since the

decoder is attached to the roof. All the electronics and lights stay in the

roof of the shell. This is the general layout I use most of the time. I am

using all LEDs from now on.

Some test running before disassembly

12-13-15

12-20-15

Fuel Tank and Train Control Box

The

fuel tank was too long so I shortened it almost 1 inch. For the first time I am

using 3D printed parts without getting them cast in brass on a brass model.

This is the train control box.

1-3-16

Rooftop “Torpedo” Air Tanks

I

decided the original Sunset torpedo air tanks were too wrong to keep. Among

other things they are too short. Bill’s Train Shop http://www.btsrr.com sells a tank kit that is

just perfect including the piping. The old tanks

had to go to use the BTS kit. The before photo is at left. They are various

stages of laying out the new holes, filling on the old holes, tapping the new

tanks and tank replacement completed. This improvement is 1 of the most

important changes I made.

1-12-16

PRR Antennas & Ultrasonic Cleaning

There

is great angst and procrastination in adding antennas to a PRR loco. Getting

the stanchions in the correct place is important. I am obsessed with making

them in a straight line. That requires good measuring and layout. I have never

seen real PRR stanchion placement drawings. Finding overhead photos is

difficult. In this case I started with the stanchions on either end of the air

tanks and used them to set the shorter stanchions on the tanks. I could have

never soldered the stanchions to the air tanks without my resistance soldering

unit. I worked my way out in both directions until I was done. The shorter cab

stanchion was the last installed. Note that the steam generator exhaust stack

has been moved. It took all this time to notice it was on the wrong side of the

short hood!

I

got very lucky and won a photo on eBay of the Trainphone receiver coil of 8553!

I am sure it is an EMD photo. So I had a good reference to make my receiver

coil. Soldering the coil to the roof was a challenge without it falling back

into 3 pieces. Again, this work was not possible without my resistance

soldering unit.

I

used solder flux for a lot of the detail work. This concerned me that there was

some flux left in areas I could not reach with the blast gun that could corrode

later and push the paint off. So I used my ultrasonic cleaner machine for the

first time. There are brass ultrasonic cleaning solutions that I was scared to

use, so I used water and some Dawn dish soap. I was skeptical that it was doing

anything, but after a few minutes the water was not as clear and there was some

debris in the bottom of the tank.

That

body modifications are done at this point. Onward to

completing the new handrails.

I still blasted the body just before paint.

2-17-16

I

must not have taken any in progress photos of making the handrails. They are

very fragile.

2017 Reboot

Added 5-28-17

Procrastination

hit again, that put 8553 back in the box for another 18 months. Among other

things in that time, I made a Reading Trainmaster, Reading SW1, and completed

my 2 PRR L1 and 2 PRR

I1. Completing the 4 steam locos was a major accomplishment.

Again,

this has taken a turn to become a different and better model. I am now

frequently using WOW4 decoders with a Keep Alive capacitor bank. The original

Tsunamis are going away. I also switched to the Overland HO diesel driveshafts.

The 3D printed U Joints I designed were fun to make, but very brittle. I had my

doubts even in back 2015 that they would durable enough to last as a wear part.

The Overland driveshafts are a little short so I used heat shrink tubing to

help keep them concentric. I used a barbeque lighter to shrink the tube with

the motor running! I skimmed the heat shrink tubing with a Dremel drum sander

to try and balance that rotation a little more. It helped a bit.

Since

I changed a few things in the drive I threw it back together for another test

run. It has never run before with the detailing done. I am pretty happy with

the results. I like flame throwing headlights. These LEDs are awesome. I found

a few distracting light leaks that have to be fixed before painting.

Completed 6-10-17

The

fuel tank is completely open without a gear tower, so it was perfect for adding

weight. I saw a mention of “Liquid Gravity”, instead of my idea to pour molten

lead in risking complete disassembly. It was a literal 2 minutes. It worked

very well. I gave a liberal dose of ACC. An hour later is it a rock. I gained

almost 6 ounces.

It

worked well, but was a little boring instead of the molten lead. Maybe

sometimes boring and safe are good! I still think it is a steel shot blast

media, not anything developed for model railroad use.

Updated

2-25-18

All photos and content © Lanes Trains 2005-2018