|

Reading G-1sb 204 Reading G-1sb 202

Reading

G-1sb 204 In

putting more “R” in my PRSL modeling, in 2015 I started significant projects

to better represent the Reading in my rolling stock. I have been casually

buying Reading rolling stock built by others over the years. With the passing

of Frank Titman and liquidation of his layout, I bought a lot of Reading

freight cars. Besides the Reading I-8 Camelback, and I-10sa, I had no true

passenger locomotives. When Frank’s G3 was sold many years ago I had no

interest in the Reading. Later when my focus changed to mostly PRSL modeling,

I knew I needed a Reading Pacific. I made a deal with Fred Rouse, former owner

of S Scale Loco & Supply

to build it. The book “The Reading Railroad’s Mighty

Pacifics” by Benjamin Bernhart was heavily used as a reference in this

project. |

|

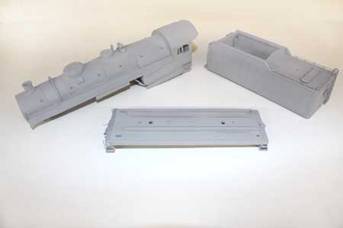

My

intention was to build a very nice representation not a rivet for rivet brass

model. The loco arrived February 2015 for me to take over and finish it. Fred

chose to use the American Models Pacific for the starting point. It was an

excellent decision as it runs very well.

I

also bought a detailed American Flyer tender shell years ago from John Hall in

anticipation for this project. It is stock American Flyer length instead of

Frank’s custom chopped and reassembled shells. My tender is not really correct

length for a G1 in this era, but again “good enough”.

I would like to thank Fred Rouse for building this loco for me.

I have been having such a great time running it.

This

is the first major project I completed since I got my own 3D printer. It was

very convenient to be able to design and print the parts needed the same day.

If the part was not quite right, change it and print again.

While

I did not make the loco, the start to finish effort was a very involved

significant project only second in effort and complexity to my PRR K4 5495

project here. I did more “bodywork” with auto body

putty, multiple coats of primer, and wet sanding than ever before.

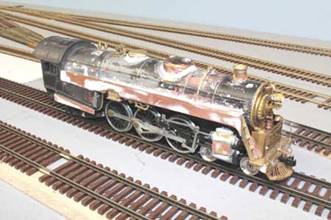

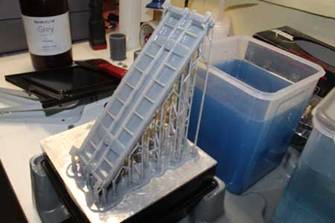

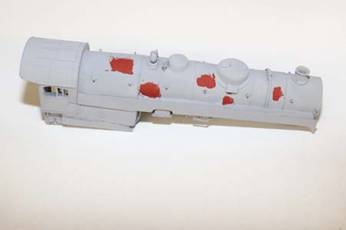

First Photos

These are the first photos when I got the loco only from Fred

Rouse.

2-17-15

Threaded Inserts

The

American Flyer screws are very large. I wanted to use 2-56 screws. I tapped

some square brass tubing and glued them as threaded inserts in the tender

shell. It worked very well.

These are some of the parts I designed and 3D printed.

The

face of contact with all the supports is usually the worst and mostly not

usable without significant clean up. This needs to be considered in the design

process.

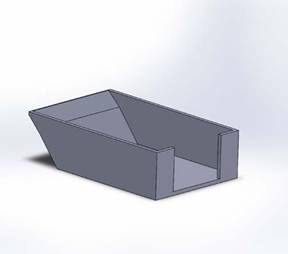

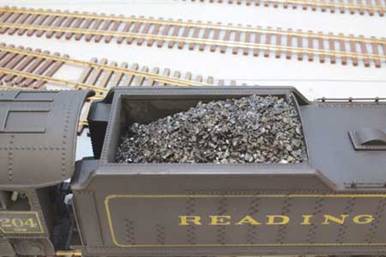

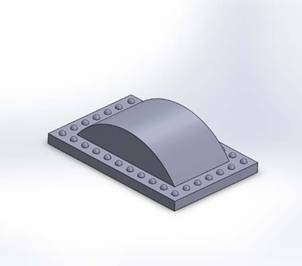

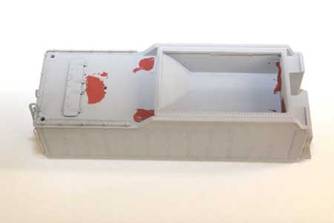

Coal Bunker

Most

of the American Flyer tenders I have on scale locos have a heaping coal load

with coal sprinkled on top of the fake plastic load. I wanted to show a

partially consumed coal pile so I cut out the plastic and printed a coal

bunker. The effect was so worth the effort. It wound up being watertight as

well when I was making the coal load.

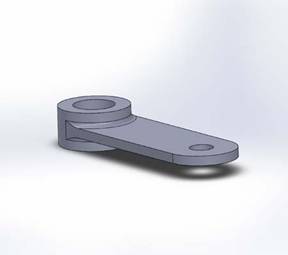

Drawbar

It was very easy to make varied lengths in Solidworks until I

got what I wanted.

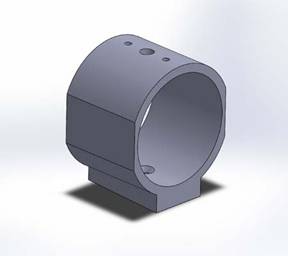

Motor Mount

I angled the bottom a bit to help with the very

offset driveshaft. There are 2 nylon screws on the top holding the motor in

place.

Numberboards

I used 1 I had cast in brass for the boiler front. The tender

numberplate was right from my printer.

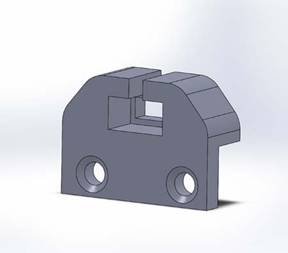

Power Plug Bracket

This

bracket holds the Miniatronics 2 pin power plug form the tender to the loco in place on the

frame at the drawbar of the loco. Just having fun making parts!

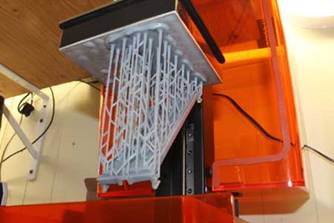

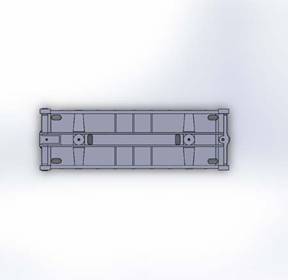

Tender Floor Base

The

tender base is the largest item I have ever printed. It JUST fit in the build

area of my printer. I don’t claim the tender base is completely accurate but I really like it.

3-29-15

This

is the first round of designing for the tender floor. There are always changes

and things you cannot account for until you try it. Getting the coupler height

correct is always a guess.

The

first photos are of the first floor just completed and still on the base of my

3D printer. You can see how it JUST fits! This was the fastest print speed to

get it done which was still 3 hours. There are 2 slower speeds that give a much

better finish. The tubs are alcohol which cleans and cures the material. The

whole base and lattice like support structure is waste and cannot be reused.

The U shape near the drawbar pin was a design feature as first point of contact

to the build plate. It is also waste.

After some changes this is the final version. I had to remove

some ribs because they hit the wheels.

And the final print after painting.

Water Deflector

4-11-15

I

made the first test tender base and temporarily put a decoder in for some test

running. I had to get some Reading cars out for a proper first run!

Some Primer and Bondo

5-27-15

Actually

I used Floquil primer and an auto body product called NitroStan.

It is a one part filler that dries quickly. It has a

finer consistency than the Squadron putties. Some significant effort was made

here with puttying, and repeatedly wet sanding with more primer sprayed, only

to be wet sanded again. It was very time consuming. At some point you just have

to say enough and call it done.

6-14-15

Another quick test run before final

paint.

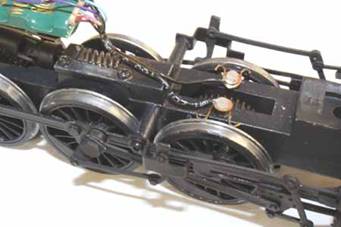

Power Pickup

It

is very time consuming but mandatory to have good operation. I make as many

wheels as possible pickup power. I use phosphor bronze wire for the pickups. I

cut grooves in the back of the wheels to keep the pickups from wandering and

shorting. Everything is isolated with nylon screws and washers. There is some

difficulty in getting the pickup tension just right so it picks up power but

does not create wheel drag. I also regularly oil the grooves. It does not seem

to have any effect on the power pickup.

I

am also showing where I mounted the decoder. It almost fit on top of the motor

but I had to make this bracket instead. Note I use a lot of Miniatronics plugs

throughout the design for easy maintenance.

Decoder and Electronics

I

used a TCS WOW Decoder for the first time. I mostly use Soundtraxx Tsunamis

previously. The WOW was recommended to me because I did not have a sound cam to

utilize. It was a bit difficult at first as 1 change takes multiple CVs to

program. I have warmed up to the WOW a bit and might use 1 again. There is a

very slight random change to the chuff sound and rate when running at a

constant speed that I like. With this loco forward I am using all LEDs for

lighting. The Railmaster Deep Bass has been my speaker of choice for many years

now. They come already sealed in an enclosure baffle and sound great to me. I

put the speaker right under the stack pointing up. That is where the sound

really comes from anyway.

Completed Model

Rods Down Portraits

8-2 to 9-6-15

I have taken a LOT of photos of the finished model.

Updated 2-25-18

All

photos and content © Lanes Trains 2005-2021